Procure to pay P2P is an important part of any company’s supply chain operations. Ensuring the full procure to pay cycle is running smoothly from contract management, purchase requisitions, timely payment, and everything in between is critical.

The business case to justify a spend analysis and limit high costs within procurement and ap is quite obvious and has a significant return on investment.

When looking at the challenges in procure to pay processes it is important to understand there are two major components, the internal component, and the external component. The internal part of managing purchase orders and the procurement processes is where companies should focus first. These are the steps that are much easier to effect in a short period of time (erp system, p2p solution, accounts payable, etc.). Once this side of the process has been optimized it is then time to turn to the external part, analyzing vendors, delivery times, and more.

Let’s look at some of the common challenges faced in procure to pay p2p:

Â

Improve PO Cycle times

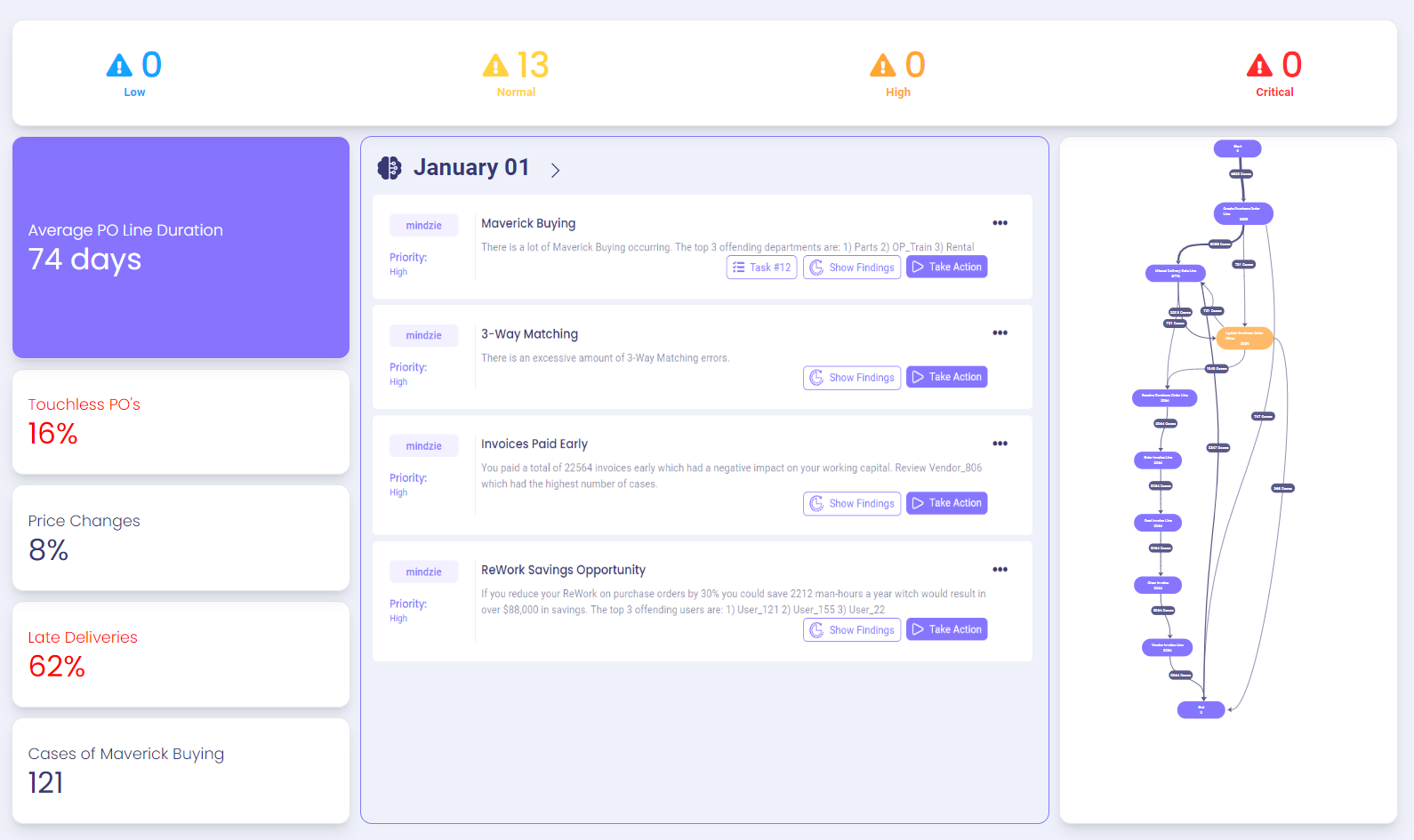

Quick wins can come from improving the internal component, the part that you control. Looking at the time it takes from PO creation to approval/confirmation is an important first step. Lengthy delays in purchase order approval and confirmation can add wasted days to the process and negatively impact your overall operation. Leverage process mining tools you can quickly identify where the bottlenecks so you can take action to mitigate them.

Â

Reduce wasted hours spent on change/corrections/update

Every business has waste, the goal when it comes to operational efficiency is to try and limit that waste wherever possible. Changes and corrections to things like a purchase order item’s price not only adds time to the process but also is a major source of wasted person hours. When you leverage process mining to analyze and manage procurement you can see the complete picture of what is happening. This will allow you to better understand if there is a problem with things like your master data and you need to update specific product pricing as an example.

Â

Late Delivery times

Delivery timeliness is a critical component to any supply chain operation, remember the longer it takes you to get product the longer it takes you to deliver product to your customers and turn your orders into cash. Getting to the root cause for late deliveries and other challenges is critical, yet very difficult. Root causes can be made easily apparent with process improvement tools.

Â

Costs Per Invoice

Reducing cost per invoice is high on the list of most CFOs. The procure to pay process is a major driver of payments and as such, it is important that it is reviewed as part of optimizing any companies cost per invoice. Looking at the number of steps and how many changes and corrections need to be made before an invoice is completed will uncover valuable opportunities to improve this metric.

Â

Slow Invoice Process Time

Remember that the overall goal is to improve your process efficiency, a significant part of this is your relationship with your vendors. How and when you pay them, and more specifically paying them on time, will have an impact on your ability to negotiate better terms or make sure your orders are delivered in front of your competitors. Slow invoice process times can mean that your vendors are paid late or even worse delay your next order while they wait for payment from the first one. Understanding process durations, steps, bottlenecks, and exactly where things are getting stuck through concepts like process mining helps you get to the bottom of these issues.

Â

Compliance and Audit

Most have heard of the term maverick buying, or maybe you know it by another name, but it is when someone in your organization makes a purchase without an approved purchase order. Now many believe their system is designed to stop this from happening, which is true however, what they fail to remember is that real life happens outside the system. What tends to occur in these situations is that the actions are recorded in order in the system (purchase order, receive goods, invoice) however the dates when these events actually happened don’t follow that order. This is just one example where tools that have the ability to understand the activities and steps in a process, rather than just a number, stand above standard BI tools as they allow you to manage and monitor compliance challenges.

Â

These are some of the most common procure to pay challenges, but definitely not the only ones (this list could go on for days). That said when exploring leveraging a process mining tool to help you overcome these challenges it is important as an organization that you ask the right questions:

- Who in your company will use the tool?

- Is the system easy to use?

- How difficult is the setup?

- Can the solution help alert me on things I need to be aware of?

Asking these and other questions will help you make the right decision, and once you have the right tool you will be well on your way toward operational excellence.

James Henderson, mindzie